Casting of toilet bowls

Toilet bowls are produced in modern automated casting system Abadia H4. This plant has battery design with up to 8 moulds in row for high production volumes. Each mould consists from 4 parts.

| Technological properties | Value |

|---|---|

| Casting machine | Abadia H4 |

| Approximate cycle time | 25 - 40 min. |

| Max. plant annual production volume | 130 000 toilet bowls* |

* For the calculation of the annual volume of production, a model example of three-shift continuous operation is considered.

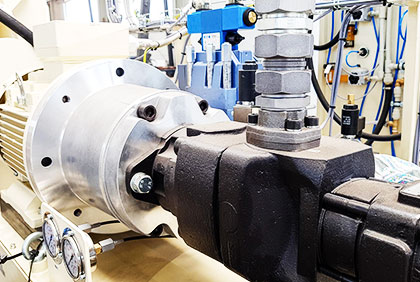

Features of the plant Abadia H4:

Max. number of moulds: 8

Max. casting pressure: 15 bar

Control system: Siemens Simatic 1200

Unloading of the products:

- manual with manipulator

- automatic with robotic arm

References by our clients

Quick contact

-

Slapy u Tábora 144

391 76 Slapy

Czech Republic - Tel: +420 383 835 197

- Email: sales (a) abadia.cz

- IČO 26092719

- DIČ CZ26092719